-

Chamber volume

- 200 litres

Basket volume

- 170 litres

-

Basic features

- Single door or double (passing trough) door version

- Stable, robust stainless steel construction

- 20 standard washing and disinfection programmes and 20 others ready to adapt to customer specifi cations

- Manually operated bottom-hinged stainless steel door to chamber with window to monitor washing process

- Integrated steam condenser

- Two dosing pumps for chemical products

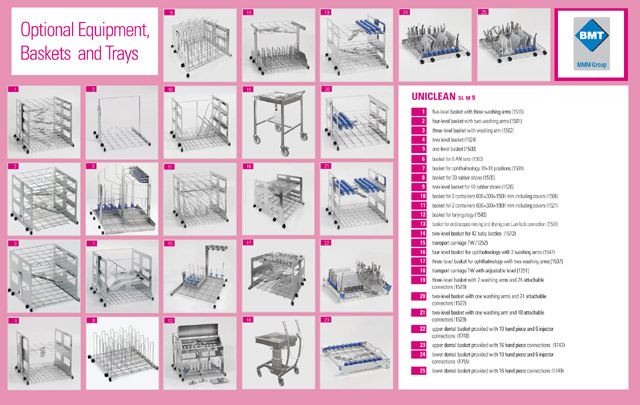

UNICLEAN SL M 9 is a small washer disinfector from the company BMT designed for associate private practices of medicine and small hospitals with central sterilisation not requiring high washing performance. It is specially designed for installation in restricted premises as a standalone device with front charging or as a double-door one, interleaving, with manually open doubledoor. This small model has built-in washing and air drying on two levels, generally used in large devices, as well as a water softener and steam condenser.

I am interested in UNICLEAN SL M 9