-

Chamber volume

- 500 litres

Basket volume

- 350 litres

-

Basic features

- Single door or double (passing trough) door version

- LCD display or 5.8’’ Touch screen

- Automatic sliding glass doors

- Two dosing pumps for chemical products

- Forced, filtered drying is achieved using a G3 class filter and HEPA H14 filter, which can be regulated according to time and temperature

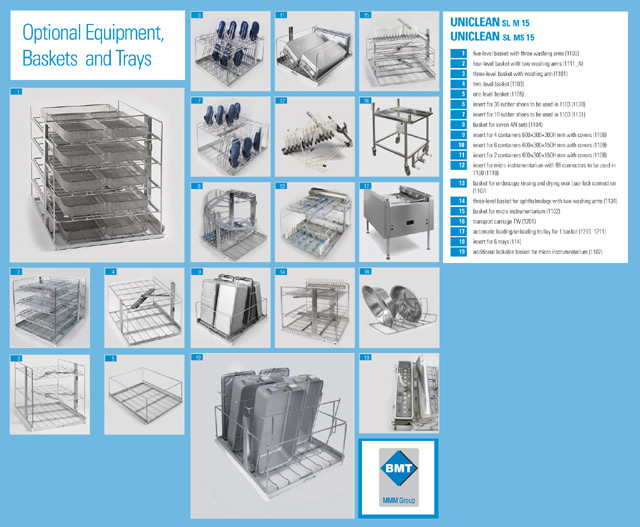

UNICLEAN SL 15 is the biggest model in the washer disinfectors line from the company BMT. This is an ideal device for large hospitals and central sterilisation units requiring high washing performance. Similarly to the small model it can be built into a wall with other devices. The device configuration is available in a double-door interlaying version for separation of the clean and dirty side, as well as a stand-alone single-door device. It is distinguished from the small model by an extensive volume of optional equipment, improving comfort and operation economy.

I am interested in UNICLEAN SL M / MS 15