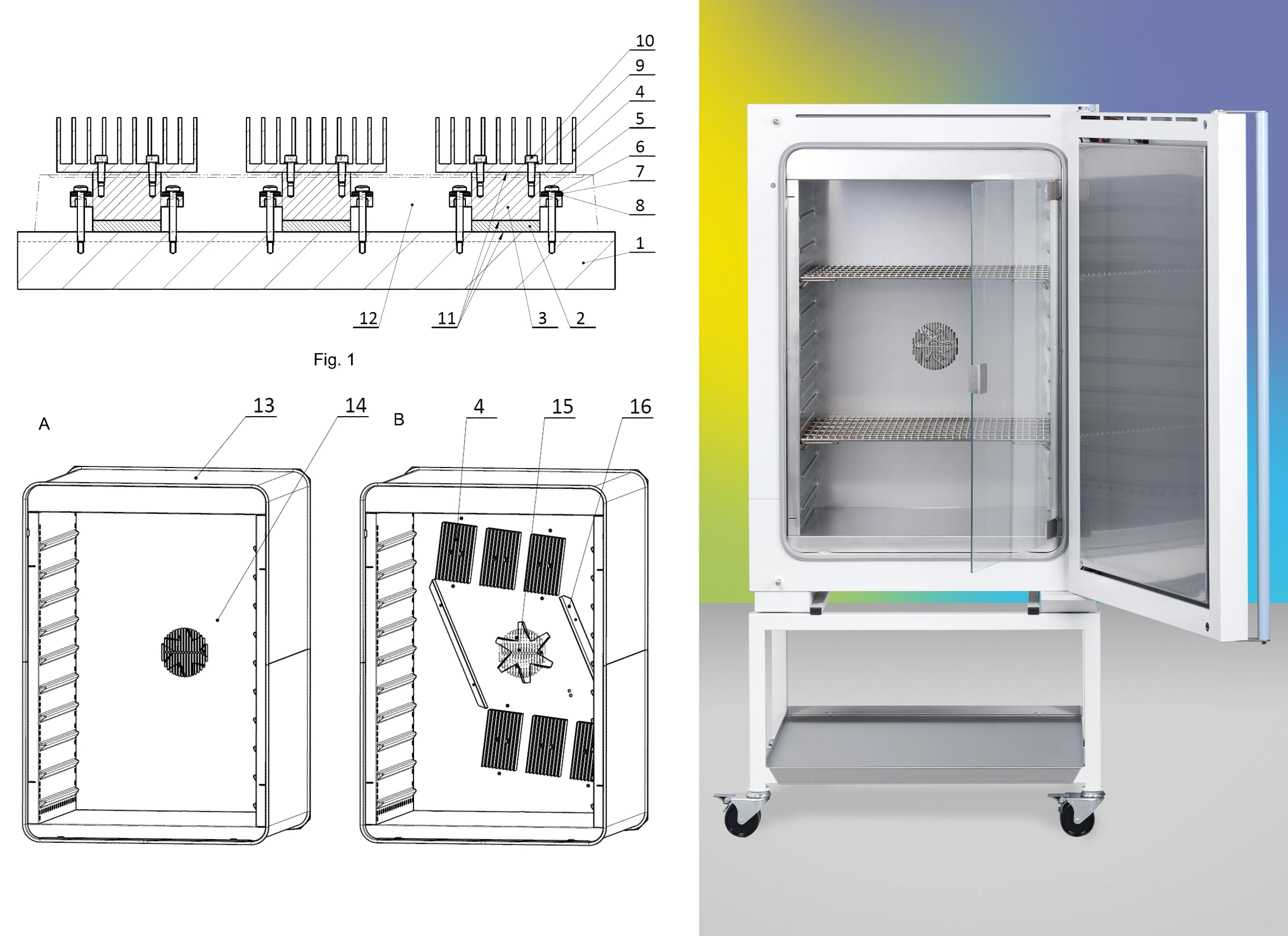

In 2023, a total of 3.55 million patent applications were filed worldwide, among them the BMT application. Shortly before the end of last year, we received notification from the patent office that our patent had been entered on 5 December 2025 in the Register of Patent Protection, following the grant of European Patent EP4528182 dated 19 November 2025 for the invention described in the patent specification. The patent is implemented in our Friocell-P products and relates to the use of a unique chamber design and Peltier modules.

Obtaining patent protection for our proprietary and unique structural solution represents a major achievement, particularly considering that only 214 patents were granted to Czech companies in 2024. For many years, the Czech Republic has experienced a decline in the number of patent applications filed. This is regrettable, as our people generate many outstanding ideas; however, there is often insufficient effort and determination to pursue or patent them. Many companies are discouraged from patenting by the relatively lengthy proceedings—often lasting 5 to 7 years—as well as by the weak linkage between patents and business practice.

While in the Czech Republic the number of granted patents has been declining annually for more than 20 years and the country ranks around 43rd in the world, China has quite literally become a “tiger,” filing 1.64 million applications, representing 47% of the global volume in 2023. It is followed by the United States (~518 thousand), Japan (~414 thousand), South Korea (~288 thousand), and Germany (~133 thousand). The ratio of granted patents to filed applications is approximately 2:3.

What makes our solution unique and what are its advantages?

Our solution ranks among the most energy-efficient systems, as it requires only a single internal fan (impeller only) for multiple Peltier modules within the chamber. By contrast, traditional solutions typically use two fans per module—an external and an internal one—or a single external fan (motor) with a shaft and an impeller inside the chamber, again for each individual Peltier module.

A shaft transfers heat from the exterior into the chamber, and an internal fan (motor) itself constitutes a heat source. In our solution, thermal bridges and heat sources are minimized to the maximum extent possible. A reduced number of fans also ensures quieter operation, and the device features smaller external dimensions, which is advantageous for our production, where a number of chamber components are shared with other TT instruments.

The heat-exchange surfaces between the Peltier elements and the heat sinks must fit perfectly. For this reason, we divided the heat sink on one side into three separate heat sinks, thereby preventing stress and potential cracking of the Peltier element due to thermal expansion. The use of a single fan (or multiple fans in the case of large volumes) for air circulation within the chamber also required optimal orientation and placement of the Peltier modules to ensure maximum cooling efficiency of the heat sinks and to prevent mutual interference.

12. 2. 2026